Industrial Gas Springs – Push Type

GS-28-550

Individual stroke length and extension forces

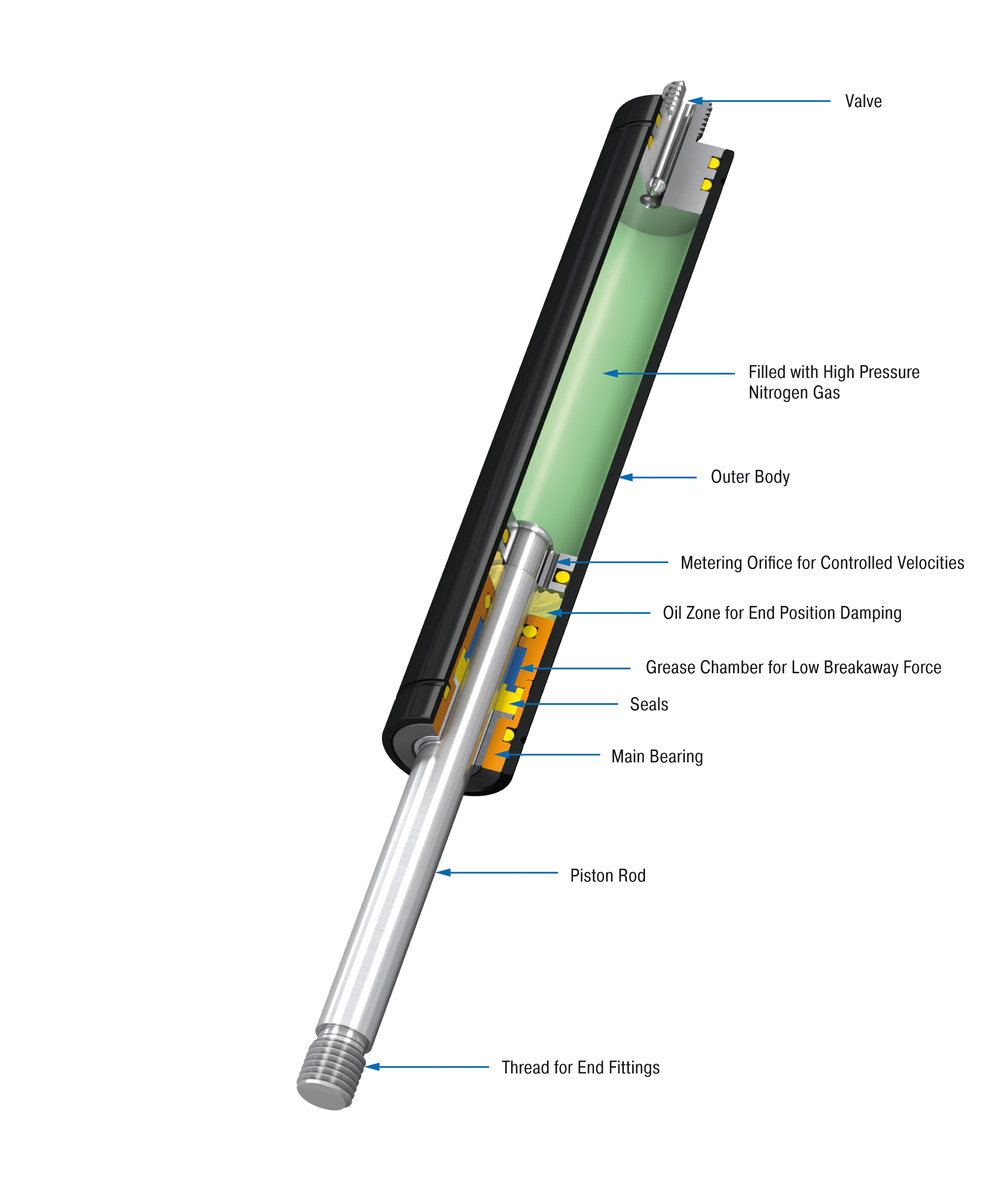

Valve Technology

Extension force max. 303 lbs

Stroke 21.65 inch

They are filled according to individual customer pressure requirements and may be adjusted later by use of a built-in valve. ACE provides free calculation support and designs the gas springs with mounting points specifically for the particular application. A variety of accessories makes assembly even easier and allows universal application of the gas springs.

CAD Drawings

Product-Downloads

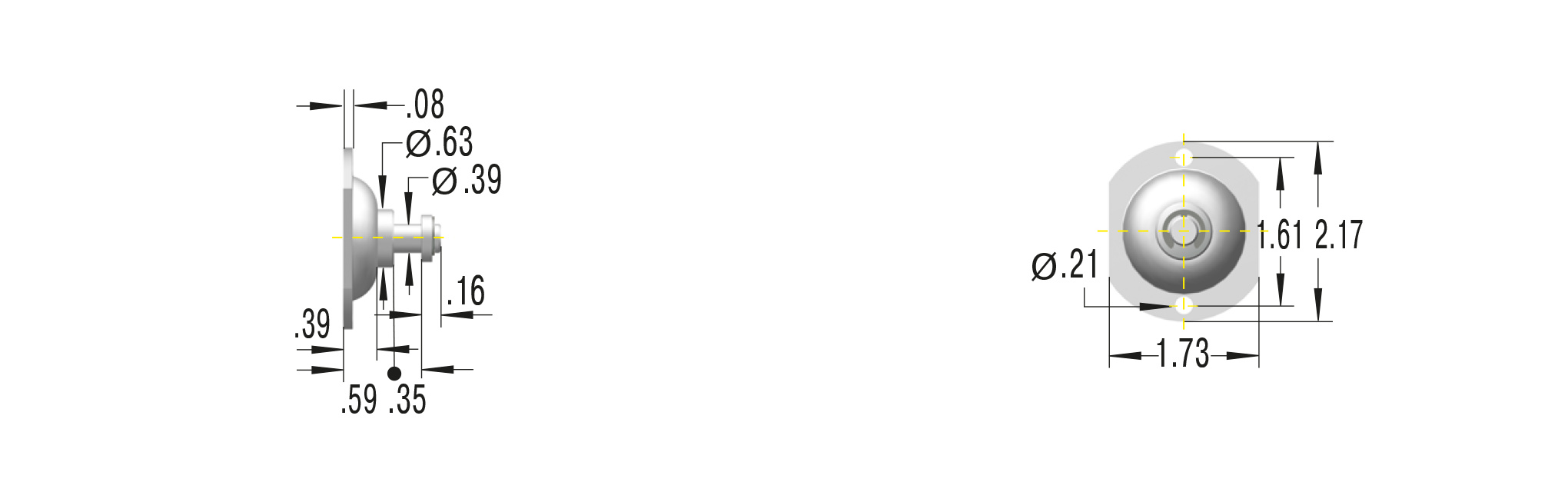

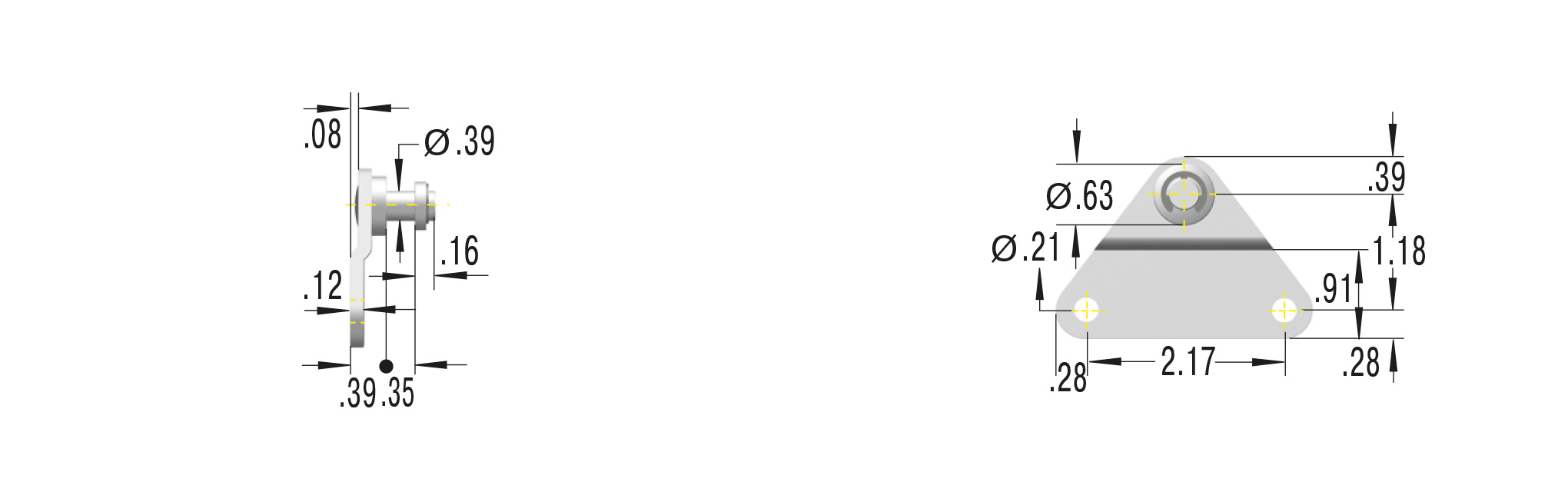

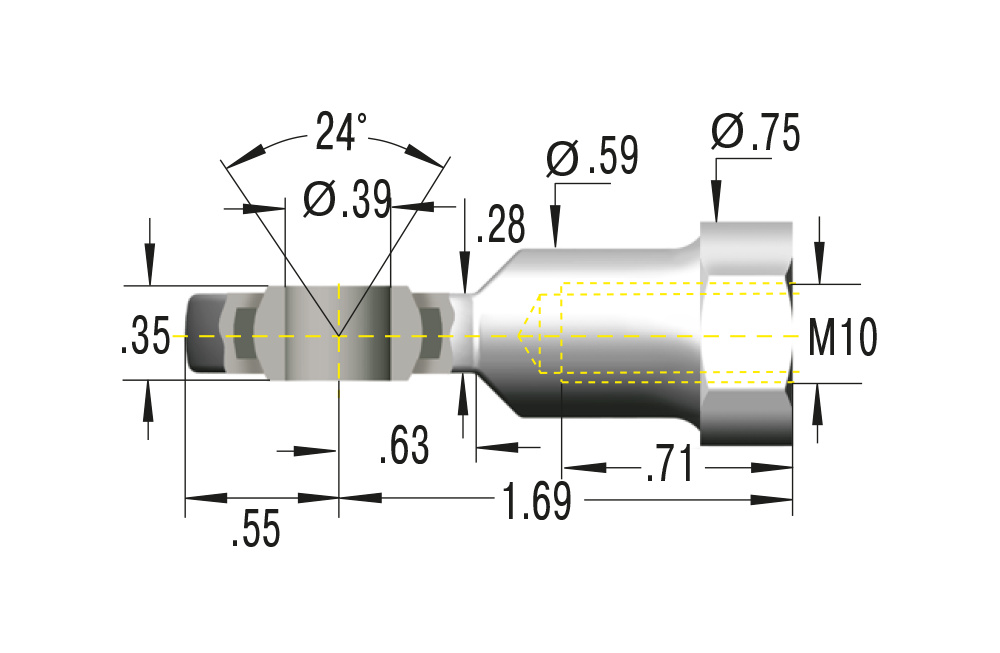

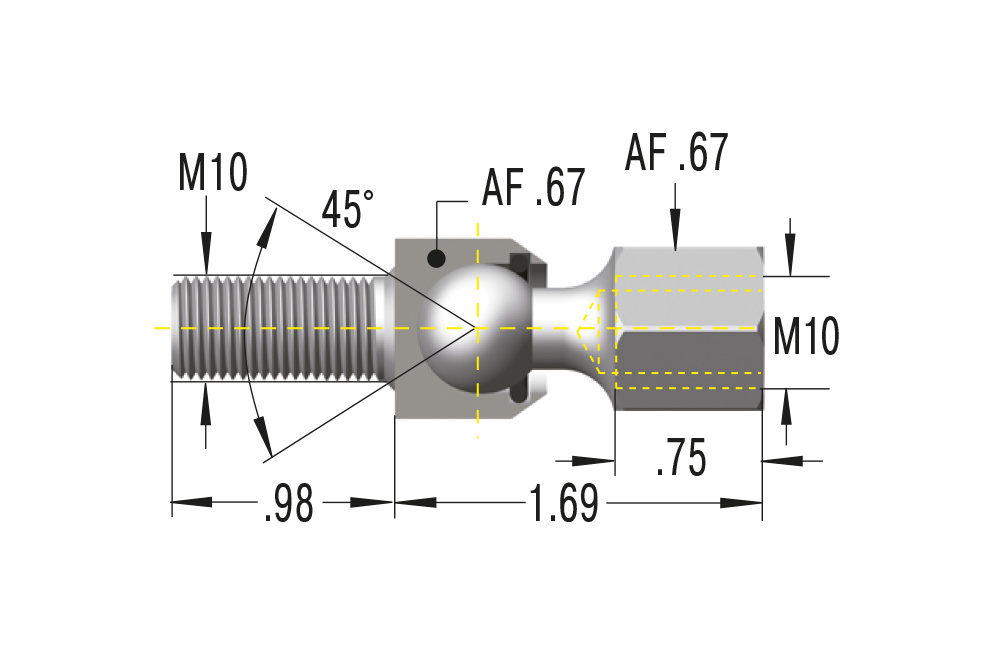

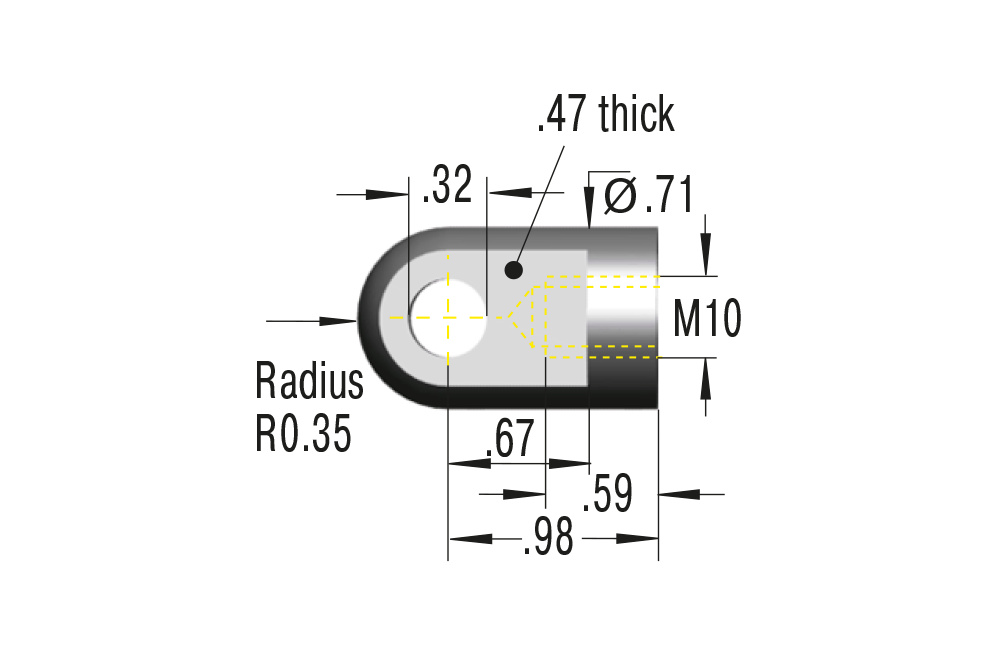

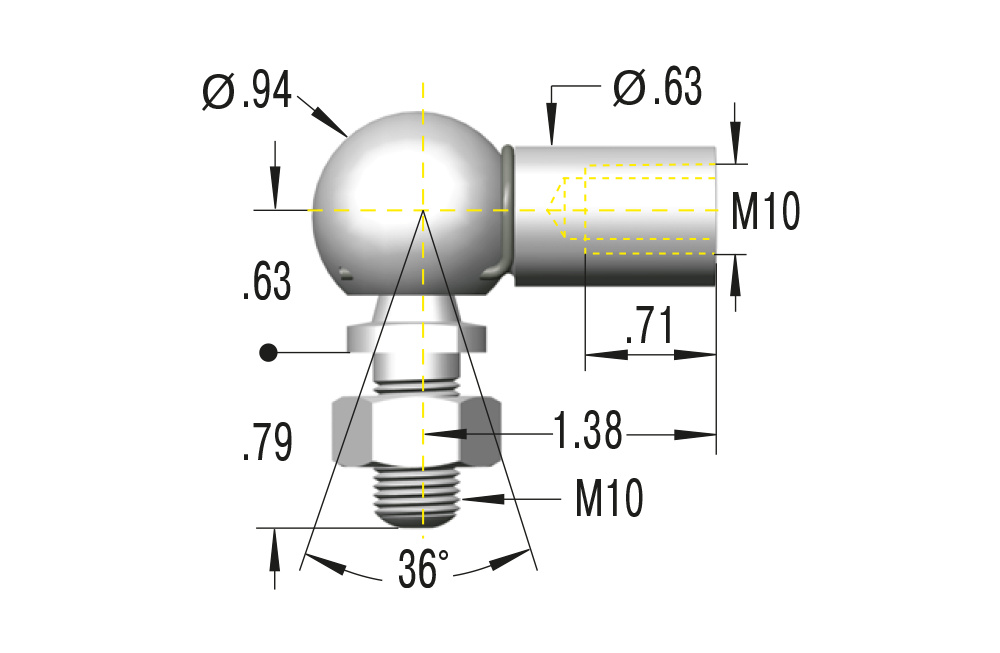

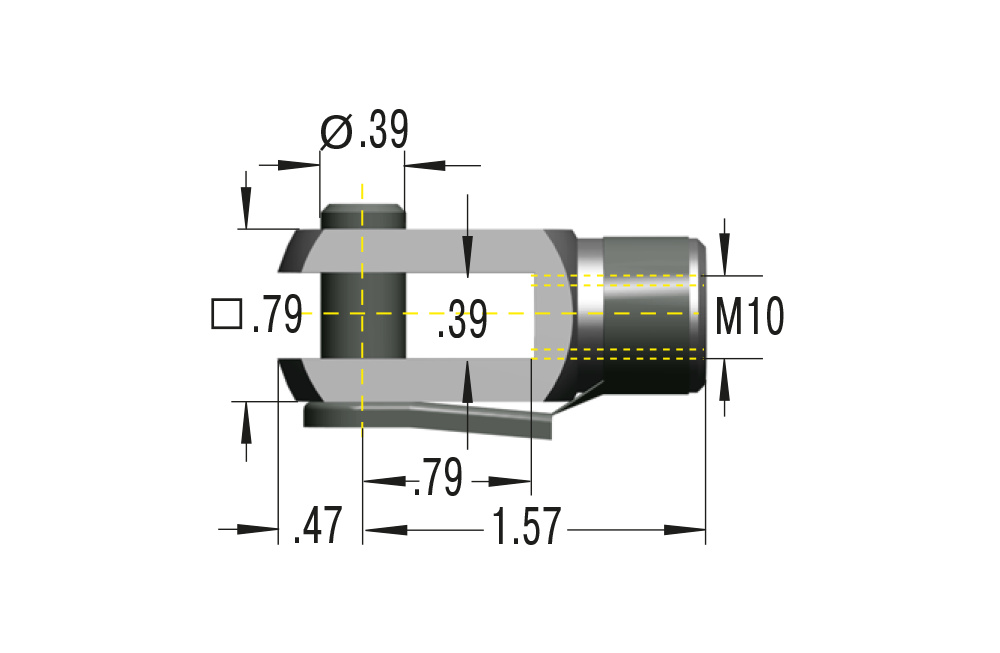

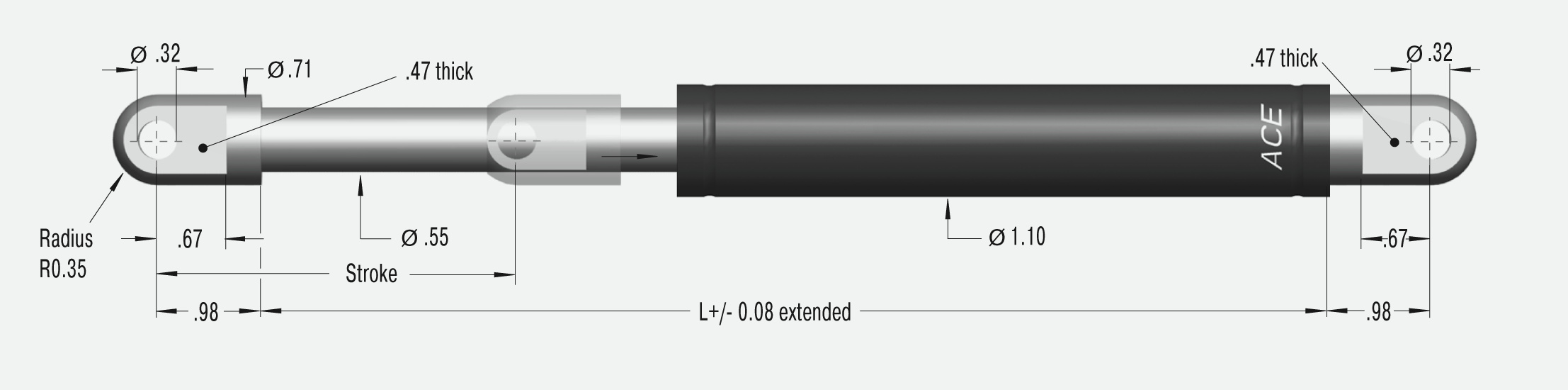

Dimensions

| Stroke | 21.65 inch |

| L extended | 45.75 inch |

Technical Data

Extension force max. 303 lbs Piston rod diameter Ø 0.55 in Progression Approx. 63 % to 76 % Lifetime Approx. 32,808 ft Operating temperature range -4 °F to 176 °F Material Outer body: Steel coated with UV paint; Piston rod: Steel with wear-resistant coating; End fittings: Zinc plated steel Operating fluid Nitrogen gas and oil Mounting In any position. Hint: We recommend mounting with piston rod downwards to take advantage of the built-in end position damping. End position damping length approx. 1.18"""" to 2.76"""" (depending on the stroke) Positive stop External positive stop at the end of stroke provided by the customer. | NoteIntegrated grease chamber reduces friction and wear and optimizes lubrication. End fittingsThey are interchangeable and if necessary must be positively secured by the customer to prevent unscrewing. Safety informationGas pressure springs should not be installed under pre-tension. On requestSpecial oils and other special options. Alternative accessories. Different end position damping and extension speed. |

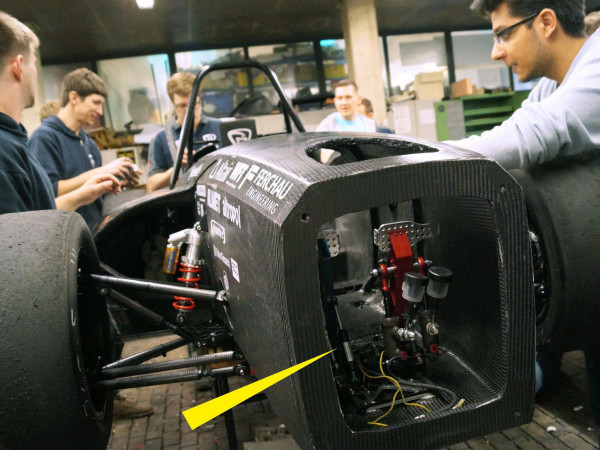

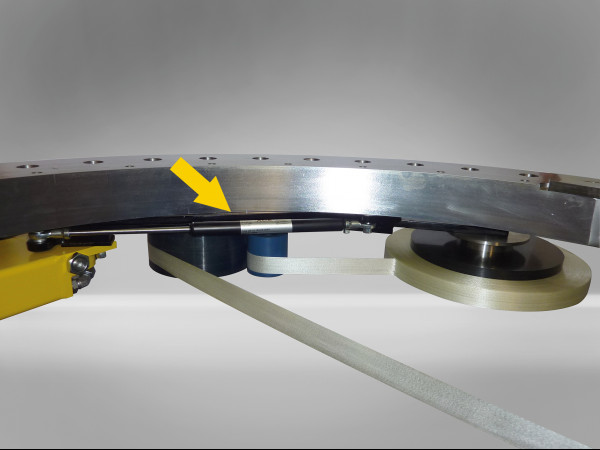

Application Examples

Application Areas

- Hoods

- Shutters

- Machine housing

- Conveyor systems

- Control boxes

- Furniture industry

- Jacking applications

- Assembly stations

- Vehicle technology

- Folding elements