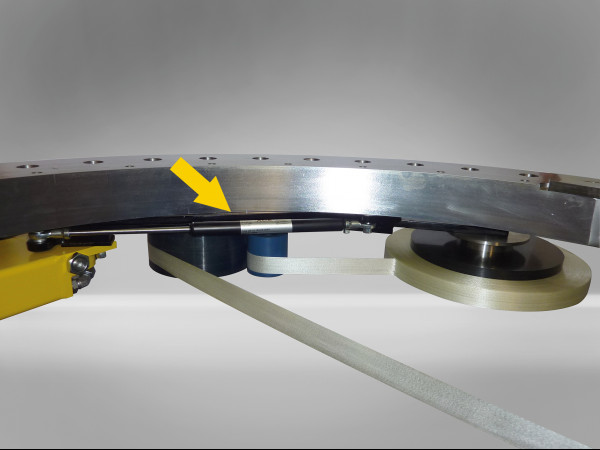

Industrial Gas Springs – Push Type

GS-15

Individual stroke length and extension forces

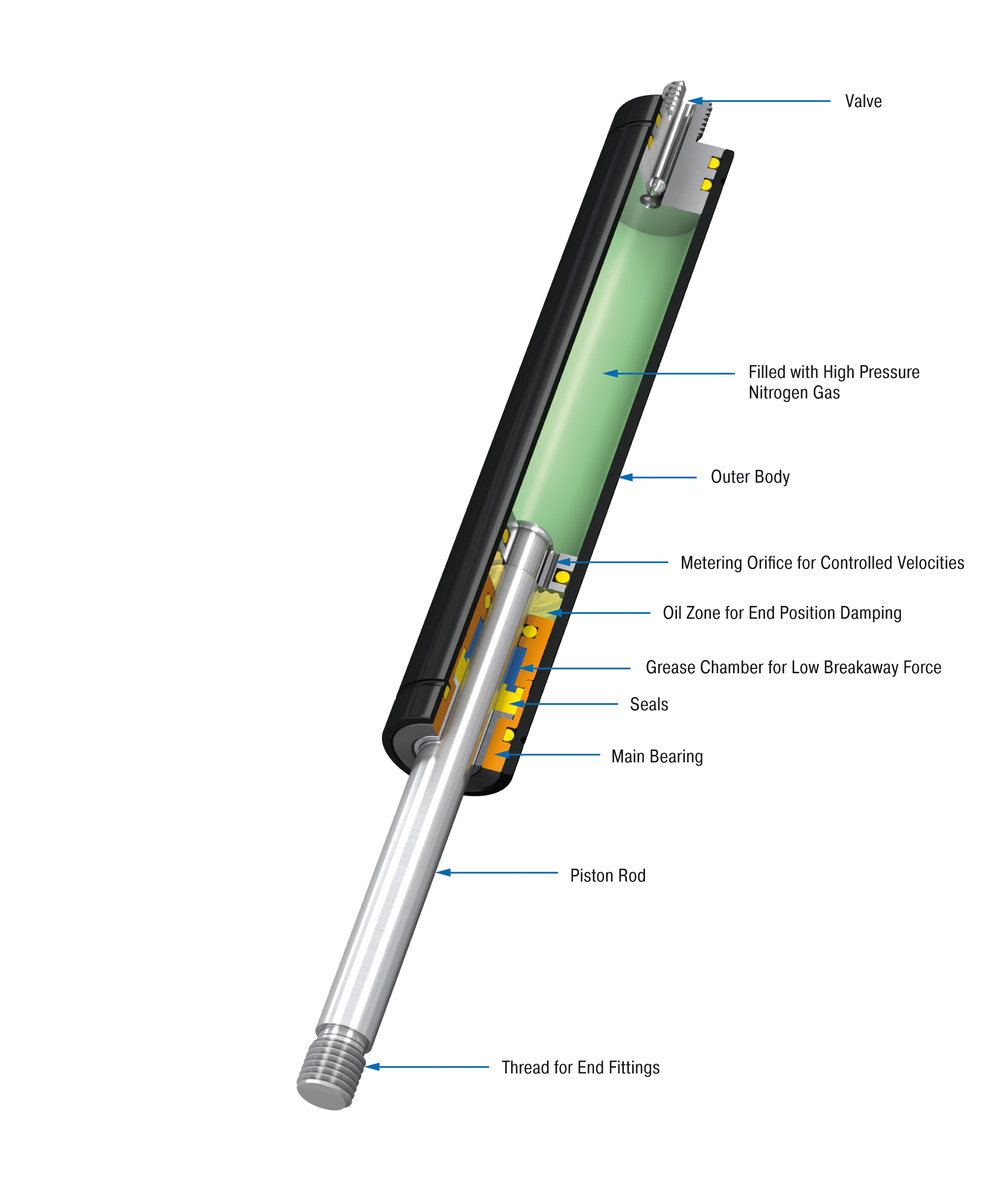

Valve Technology

Extension force 9 lbs to 90 lbs (compressed up to 126 lbs)

Stroke 0.79 in to 7.87 in

They are filled according to individual customer pressure requirements and may be adjusted later by use of a built-in valve. ACE provides free calculation support and designs the gas springs with mounting points specifically for the particular application. A variety of accessories makes assembly even easier and allows universal application of the gas springs.

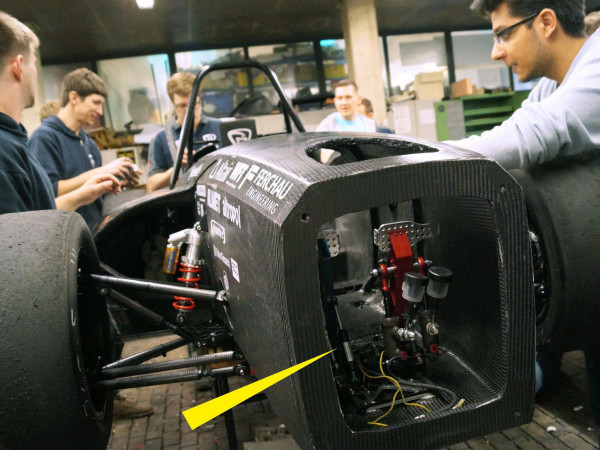

ACE industrial gas push type springs are used on covers, lids, or other components. They are used in industrial applications, automation and machine building, medical technology as well as in the electronics, automobile and furniture industries.