Industrial Shock Absorbers

MC4525-3-HT

Extreme temperature and high cycle applications

Self-Compensating, use at 32 °F to 302 °C

Energy capacity 3,275 in-lbs/cycle

Stroke 0.91 inch

These ready-to-install machine elements are recommended even under the most unfavorable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

CAD Drawings

Product-Downloads

Dimensions

_GT_TECHdraw-F_RGB-L_EN(-US).jpg)

| Stroke | 0.91 inch |

| A max. | 5.69 inch |

| L2 | 3.72 inch |

| M | 1-3/4-12 UNF inch |

| d1 | 1.65 inch |

| d2 | 1.38 inch |

Technical Data

Energy capacity 3,275 in-lbs/cycle Energy capacity at 20 °C 2,717,177 in-lbs/h Energy capacity at 100 °C 1,035,536 in-lbs/h Effective weight min. 575 lbs Effective weight max. 2,300 lbs Hardness -3 Return Force max. 22.8 lbs Return Force min. 15.1 lbs Return Time 0.03 s Side Load Angle max. 4 ° Impact velocity range 0.5 ft/sec to 16.5 ft/sec. Other speeds on request. Operating temperature range 32 °F to 302 °F Mounting In any position Positive stop Integrated Material Outer body: Nitride hardened steel; Piston rod: Hard chrome plated steel; Rod end button: Hardened steel and corrosion-resistant coating; Return spring: Zinc plated or plastic-coated steel; Accessories: Steel with black oxide finish or nitride hardened Damping medium Synthetic high temperature oil | NoteA noise reduction of 3 dB to 7 dB is possible when using the special impact button (PP). Safety informationExternal materials in the surrounding area can attack the seal components and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Do not paint the shock absorbers due to heat emission. On requestNickel-plated, increased corrosion protection, mounting inside air cylinders or other special options are available on request. Adjustable HT and LT shock absorbers. |

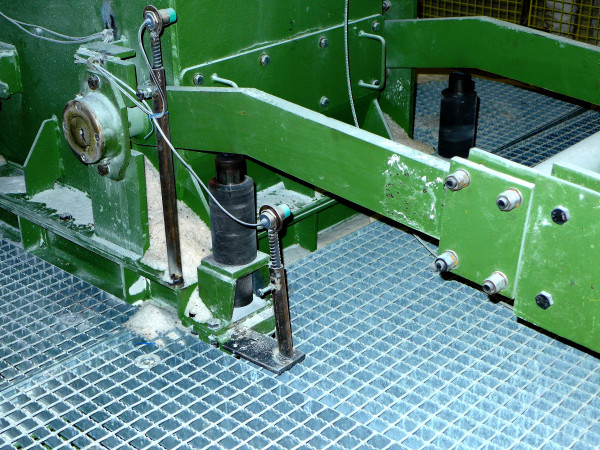

Application Examples

Application Areas

- Linear slides

- Swivel units

- Turntables

- Machines and plants

- Tool machines

- Machining centers

- Z-axes

_FA_IMG_Single-01-cut-Labels_RGB-L_EN.jpg)

_FA_IMG_Single-01-cut_RGB-L.jpg)

250-0025(-0300)_TP_TECHdraw-SL-F_Chart_RGB-M_US.jpg)

250-0324(-0325)_TP_TECHdraw-SL-F_Chart_RGB-M_US.jpg)

250-0023_U_TP_TECHdraw-F-SR_RGB-M_US.jpg)

250-0024_U_TP_TECHdraw-F_RGB-M_US.jpg)

250-0428_StopBars_U_TP_TECHdraw-F-SR_RGB-M_US.jpg)

250-0041_U_TP_TECHdraw-F_RGB-M_US.jpg)

250-0072_F-StopCollar_U_TP_TECHdraw-F-SR_Web_RGB-M_US.jpg)

250-0092_TP_TECHdraw-F_RGB-M_US.jpg)

250-0731_TP_TECHdraw-F_RGB-M_US.jpg)

250-0778_TP_TECHdraw-F_RGB-M_US.jpg)