Miniature Shock Absorbers

MC225MH3-V4A

Exceptionally high endurance with stainless steel corrosion protection

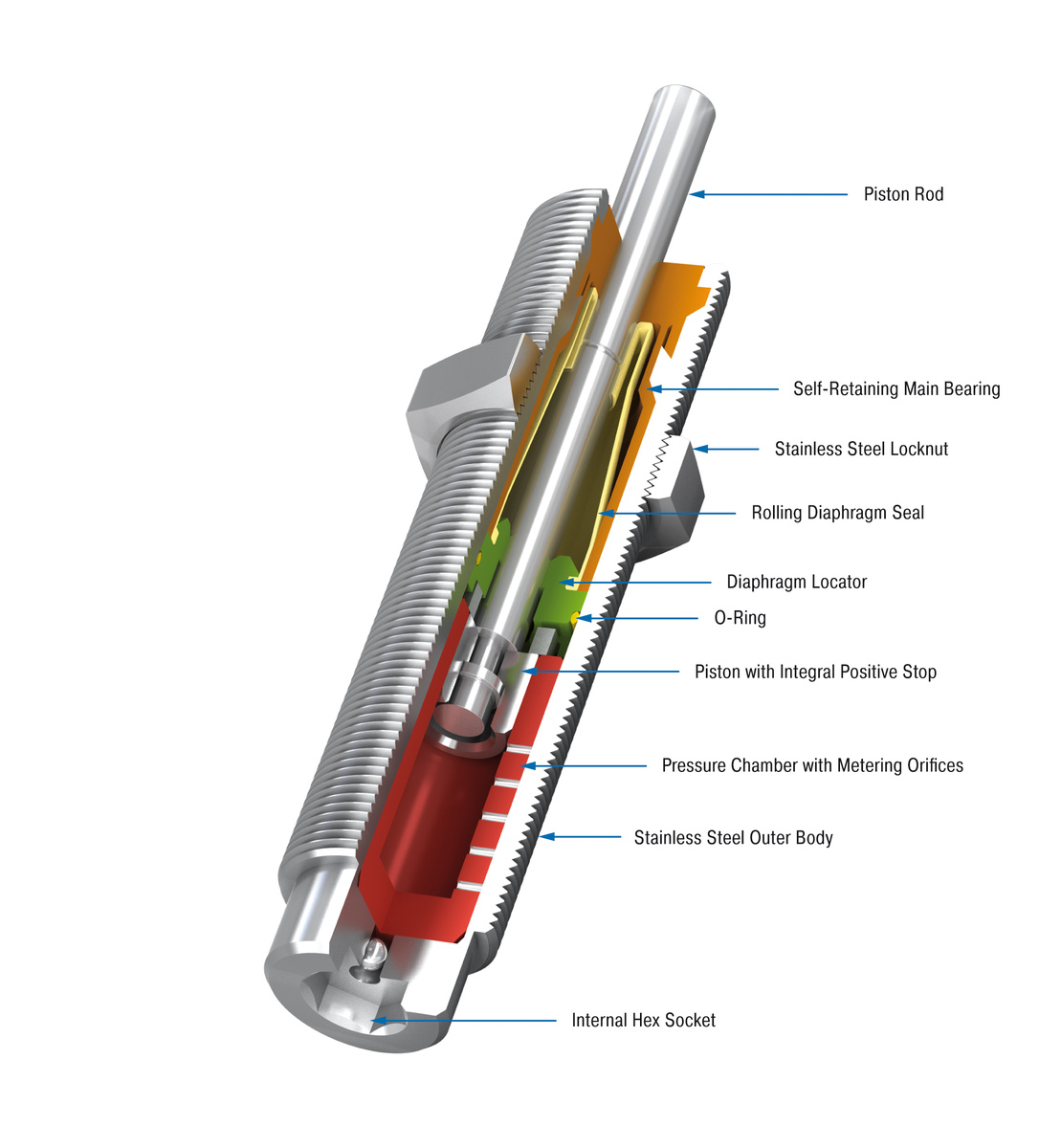

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology

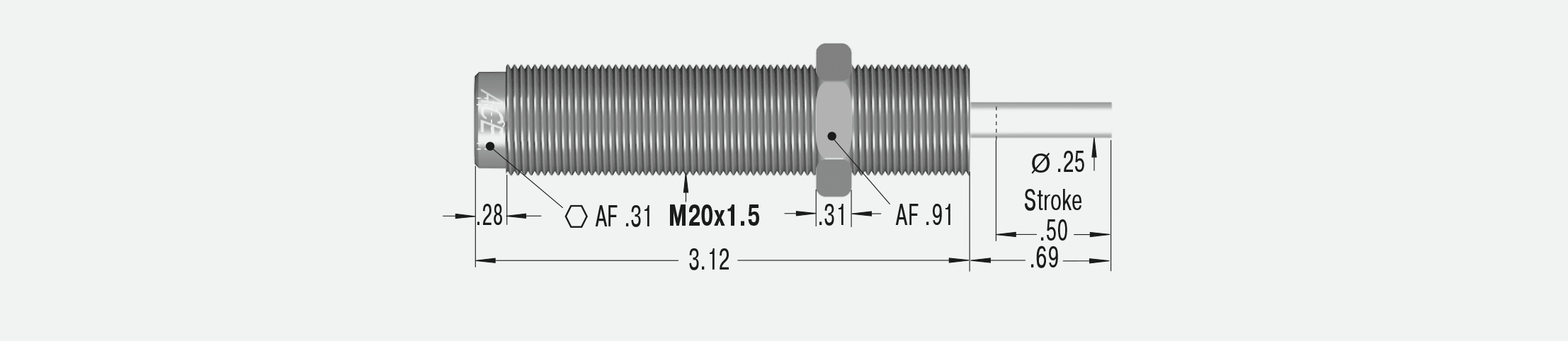

Energy capacity 360 in-lbs/cycle

Stroke 0.5 inch

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

250-0754_TP_TECHdraw-F-dim_RGB-M_US.jpg)

250-0253-V4A_M_TP_TECHdraw-F-dim_RGB-M_US.jpg)

250-0442_M_TP_TECHdraw-F-dim_RGB-M_US.jpg)

250-0434-V4A_M_TP_TECHdraw-F-dim_RGB-M_US.jpg)