Industrial Shock Absorbers

MC3650M-2

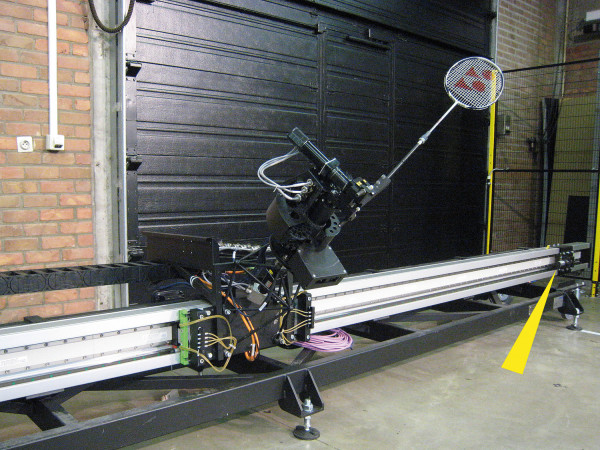

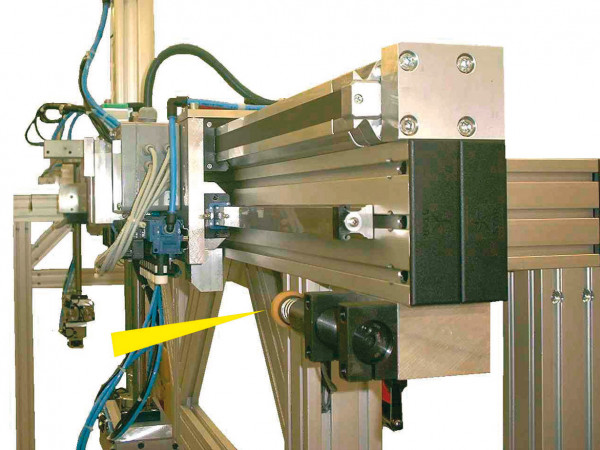

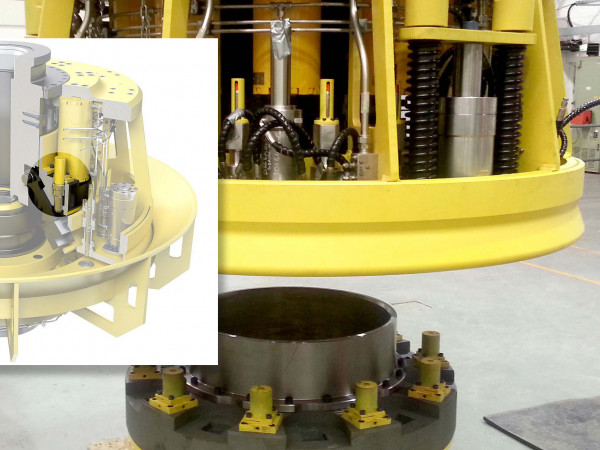

High energy absorption and robust design

Self-Compensating

Energy capacity 2,920 in-lbs/cycle

Stroke 1.91 inch

High energy absorption in a compact design and a wide damping range lead to huge advantages in practice. Alongside generally more compact designs, these small yet very powerful absorbers enable full use of the machine's performance. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

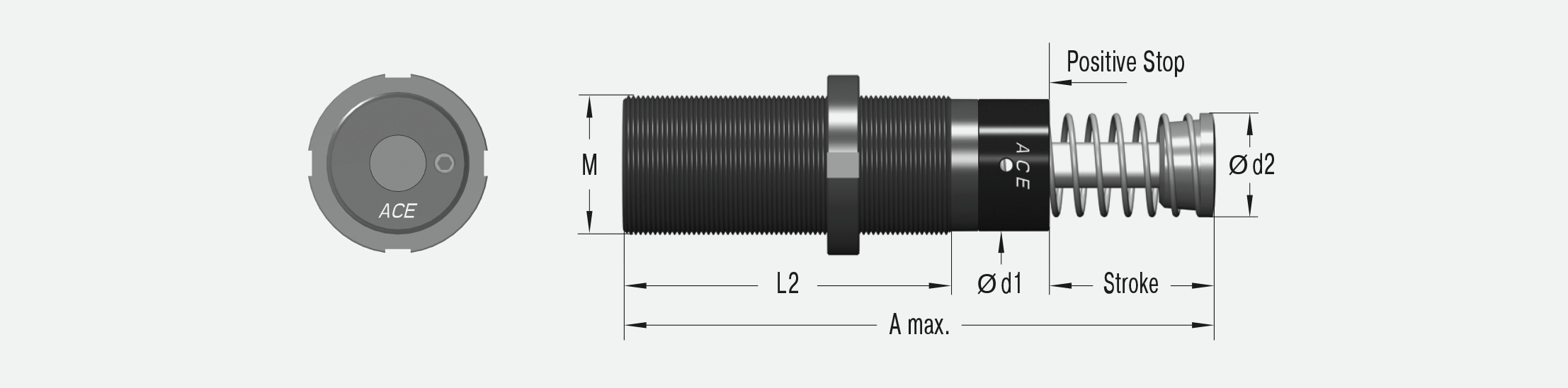

_FA_IMG_Single-01-cut-Labels_RGB-L_EN.jpg)

_FA_IMG_Single-01-cut_RGB-L.jpg)

250-0537_M_TP_TECHdraw-F_RGB-M_US.jpg)