It is easy to calculate around 90 % of applications knowing only the following five parameters:

- Abzubremsende Masse (Gewicht) m [kg]

- Aufprall- oder Auffahrgeschwindigkeit vD [m/s]

- Evtl. vorhandene zusätzliche Antriebskraft F [N]

- Anzahl der Hübe oder Takte pro Stunde x [1/h]

- Anzahl Stoßdämpfer parallel n

Key to symbols used

| Symbol | Unit | Description | Symbol | Unit | Description |

|---|---|---|---|---|---|

| W1 | Nm | Kinetic energy per cycle | 3ST | 1 to 3 | tall torque factor (normally 2.5) |

| W2 | Nm | Propelling force energy per cycle | M | Nm | Propelling torque |

| W3 | Nm | Total energy per cycle (W1 + W2) | I | kgm2 | Moment of Inertia |

| 1W4 | Nm/hr | Total energy per hour (W3 · c) | g | m/s2 | Acceleration due to gravity = 9.81 |

| me | kg | Effective weight | h | m | Drop height excl. shock absorber stroke |

| m | kg | Mass to be decelerated | s | m | Shock absorber stroke |

| n | Number of shock absorbers (in parallel) | L/R/r | m | Radius | |

| 2v | m/s | Velocity at impact | Q | N | Reaction force |

| 2vD | m/s | Impact velocity at shock absorber | μ | Coefficient of friction | |

| ω | rad/s | Angular velocity at impact | t | s | Deceleration time |

| F | N | Propelling force | a | m/s2 | Deceleration |

| c | 1/hr | Cycles per hour | α | ° | Side load angle |

| P | kW | Motor power | β | ° | Angle of incline |

Note:

When using several shock absorbers in parallel, the values (W3), (W4) and (me) are divided according to the number of units used.

|

Reaction force Q [N] Q = (1,5 · W3) / s |

Stopping time t [s] t = (2,6 · s) / vD |

Deceleration a [m/s2] a = (0,75 · vD2) / s |

Approximate values assuming correct adjustment. Add safety margin if necessary. (Exact values will depend upon actual application data and can be provided on request.)

Applications

| Application | Formulae | Example | |

|---|---|---|---|

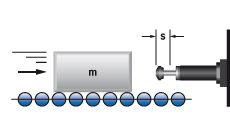

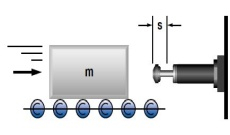

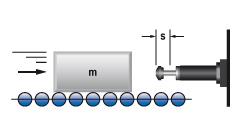

1. Mass without propelling force

|

W1 = m · v2 · 0,5

W2 = 0

W3 = W1 + W2

W4 = W3 · x

vD = v

me = m

|

m = 100 kg W1 = 100 · 1,52 · 0,5 = 113 Nm |

|

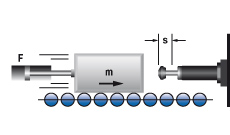

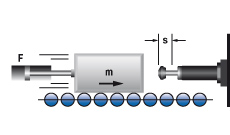

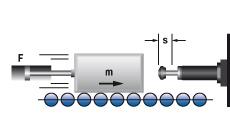

2. Mass with propelling force

|

W1 = m · v2 · 0,5

W2 = F · s

W3 = W1 + W2

W4 = W3 · x

vD = v

me = (2 · W3) / vD2

2.1 bei senkrechter Bewegung nach oben

W2 = (F – m · g) · s

2.2 bei senkrechter Bewegung nach unten

W2 = (F + m · g) · s

|

m = 36 kg

1v = 1,5 m/s

F = 400 N

x = 1000 1/h

s = 0,025 m (gewählt)

W1 = 36 · 1,52 · 0,5 = 41 Nm

W2 = 400 · 0,025 = 10 Nm

W3 = 41 + 10 = 51 Nm

W4 = 51 · 1000 = 51000 Nm/h

me = 2 · 51 : 1,52 = 45 kg

1 v is the fi nal impact velocity of the mass:

With pneumaticallypropelled systems this can be 1.5 to 2 times the average velocity. Please take this into account when calculating energy. |

|

3. Mass with motor drive

|

W1 = m · v2 · 0,5

W2 = (1000 · P ·HM · s) / v

W3 = W1 + W2

W4 = W3 · x

vD = v

me = (2 · W3) / vD2

|

m = 800 kg W1 = 800 · 1,22 · 0,5 = 576 Nm motor, coupling and gearbox into calculation for W1 |

|

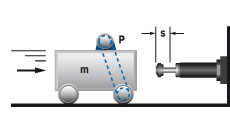

4. Mass on driven rollers

|

W1 = m · v2 · 0,5

W2 = m · μ · g · s

W3 = W1 + W2

W4 = W3 · x

vD = v

me = (2 · W3) / vD2

|

m = 250 kg W1 = 250 · 1,52 · 0,5 = 281 Nm |

|

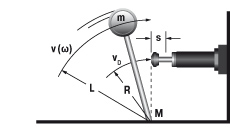

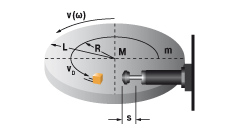

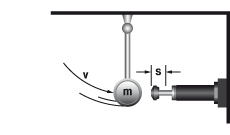

5. Swinging mass with propelling force

|

W1 = m · v2 · 0,5 = 0,5 · J · ω2

W2 = (M · s) / R

W3 = W1 + W2

W4 = W3 · x

vD = (v · R) / L = ω · R

me = (2 · W3) / vD2

|

m = 20 kg W1 = 20 · 12 · 0,5 = 10 Nm |

|

6. Free falling mass

|

W1 = m · g · h

W2 = m · g · s

W3 = W1 + W2

W4 = W3 · x

vD = √2 · g · h

me = (2 · W3) / vD2

|

m = 30 kg W1 = 30 · 0,5 · 9,81 = 147 Nm |

|

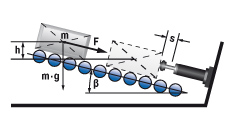

6.1 Mass rolling/sliding down incline

|

W1 = m · g · h = m · vD2 · 0,5

W2 = m · g · sinβ · s

W3 = W1 + W2

W4 = W3 · x

vD = √2 · g · h

me = (2 · W3) / vD2

6.1a bei senkrechter Bewegung nach oben

W2 = (F – m · g· sinβ) · s

6.1b bei senkrechter Bewegung nach unten

W2 = (F + m · g· sinβ) · s

|

m = 500 kg W1 = 500 · 9,81 · 0,1 = 490,5 Nm |

|

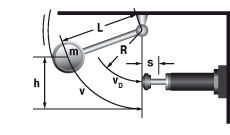

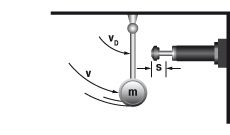

6.2 Mass free falling about a pivot point

|

W1 = m · g · h

W2 = 0

W3 = W1 + W2

W4 = W3 · x

vD = √2 · g · h · (R / L)

me = (2 · W3) / vD2

tan α = s / R

|

m = 50 kg W1 = 50 · 9,81 · 1 = 490,5 Nm |

|

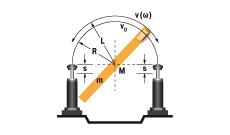

7. Rotary index table with propelling torque

|

W1 = m · v2 · 0,25 = 0,5 · J · ω2

W2 = (M · s) / R

W3 = W1 + W2

W4 = W3 · x

vD = (v · R) / L = ω · R

me = (2 · W3) / vD2

|

m = 1000 kg W1 = 1000 · 1,12 · 0,25 = 303 Nm |

|

8. Swinging arm with propelling torque (uniform weight distribution)

|

W1 = m · v2 · 0,17 = 0,5 · J · ω2

W2 = (M · s) / R

W3 = W1 + W2

W4 = W3 · x

vD = (v · R) / L = ω · R

me = (2 · W3) / vD2

|

J = 56 kgm2 W1 = 0,5 · 56 · 12 = 28 Nm |

|

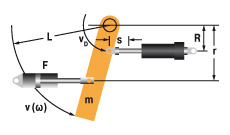

9. Swinging arm with propelling force (uniform weight distribution)

|

W1 = m · v2 · 0,17 = 0,5 · J · ω2

W2 = (F · r · s) / R = (M · s) / R

W3 = W1 + W2

W4 = W3 · x

vD = (v · R) / L = ω · R

me = (2 · W3) / vD2

|

m = 1000 kg W1 = 1000 · 22 · 0,17 = 680 Nm |

|

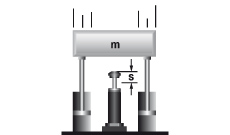

10. Mass lowered at controlled speed

|

W1 =m · v2 · 0,5

W2 = m · g · s

W3 = W1 + W2

W4 = W3 · x

vD = v

me = (2 · W3) / vD2

|

m = 6000 kg W1 = 6000 · 1,52 · 0,5 = 6750 Nm |

|

Effective Weight (me)

The effective weight (me) can either be the same as the actual weight (examples Aand C), or it can be an imaginary weight representing a combination of the propelling force or lever action plus the actual weight (examples B and D).

| Einsatzfall | Beispiel |

|---|---|

A Mass without propelling force

|

m = 100 kg

vD = v = 2 m/s

W1 = W3 = 200 Nm

me = (2 · 200) / 4 = 100 kg

FORMULA: ME = M

|

B Mass with propelling force

|

m = 100 kg

F = 2000 N

vD = v = 2 m/s

s = 0,1 m

W1 = 200 Nm

W2 = 200 Nm

W3 = 400 Nm

me = (2 · 400) / 4 = 200 kg

FORMEL: ME = (2 · W3) / VD2

|

C Mass without propelling force direct against shock absorber

|

m = 20 kg

vD = v = 2 m/s

W1 = W3 = 40 Nm

me = (2 · 40) / 22 = 20 kg

FORMEL: ME = M

|

D Mass without propelling force with mechanical advantage

|

m = 20 kg

v = 2 m/s

vD = 0,5 m/s

s = 0,1 m

W1 = W3 = 40 Nm

me = (2 · 40) / 0,52 = 320 kg

FORMEL: ME = (2 · W3) / VD2

|