Safety Shock Absorbers

SCS50-250

Low reaction forces with long strokes

High Rack Damper, Optimized Characteristic

Energy capacity 310,000 in-lbs/cycle

Stroke 9.84 inch

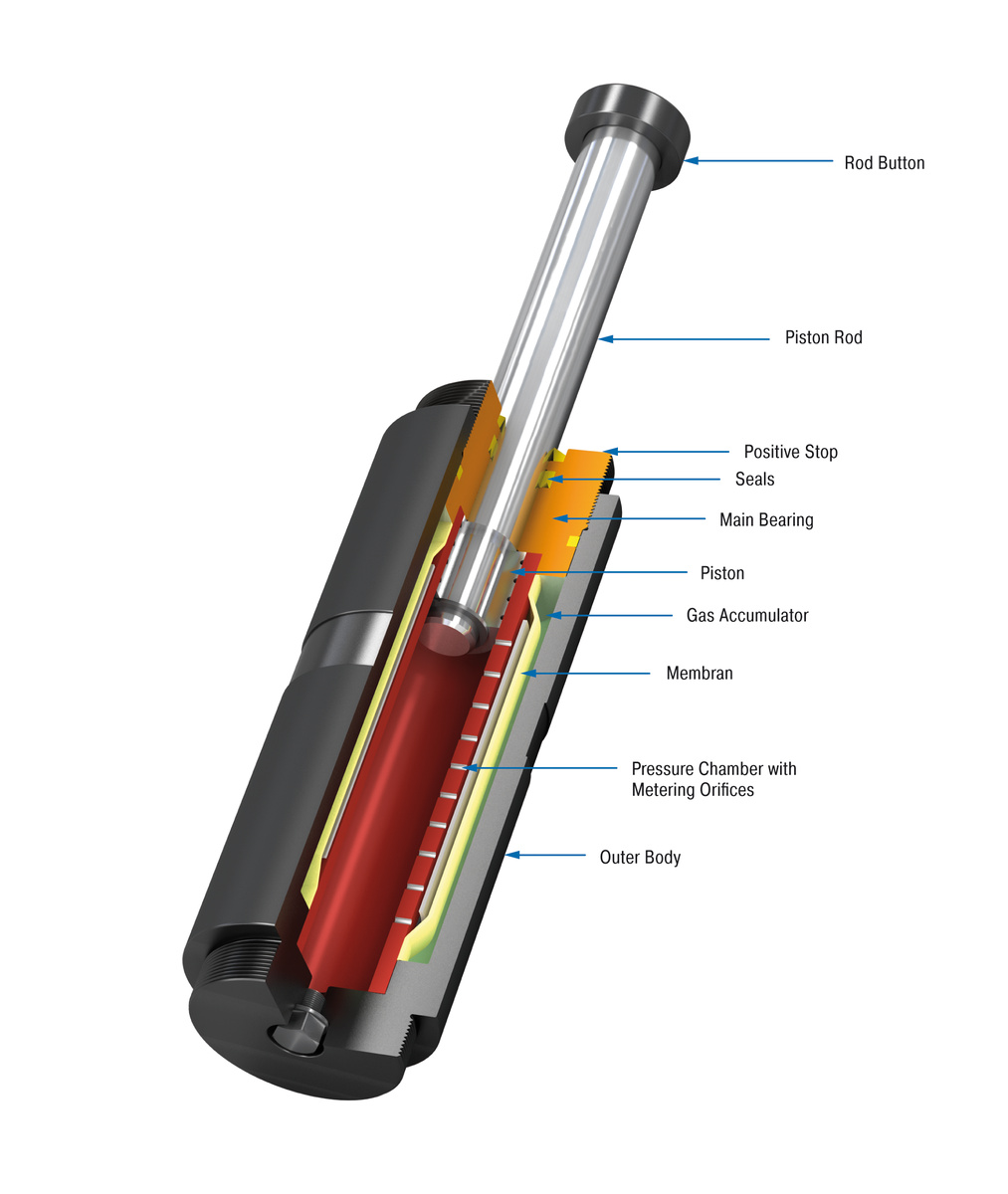

ACE uses our proprietary custom calculation program to design each shock absorber for the specific customer application. Customization helps reduce the risk of crashes and incorrect product sizing. The characteristic curve or damping characteristics of all safety shock absorbers from ACE are individually designed to the specific customer application. The metering orifices for the applications are specially calculated and produced. These tailor-made machine elements are the ideal protection because they are less expensive than industrial shock absorbers and are effective with up to 1,000 possible full load emergency stops.

CAD Drawings

Product-Downloads

Basic type SCS50

| Mounting Instructions | 56.6 kB | 5/12/2021 | |

| en_US | |||

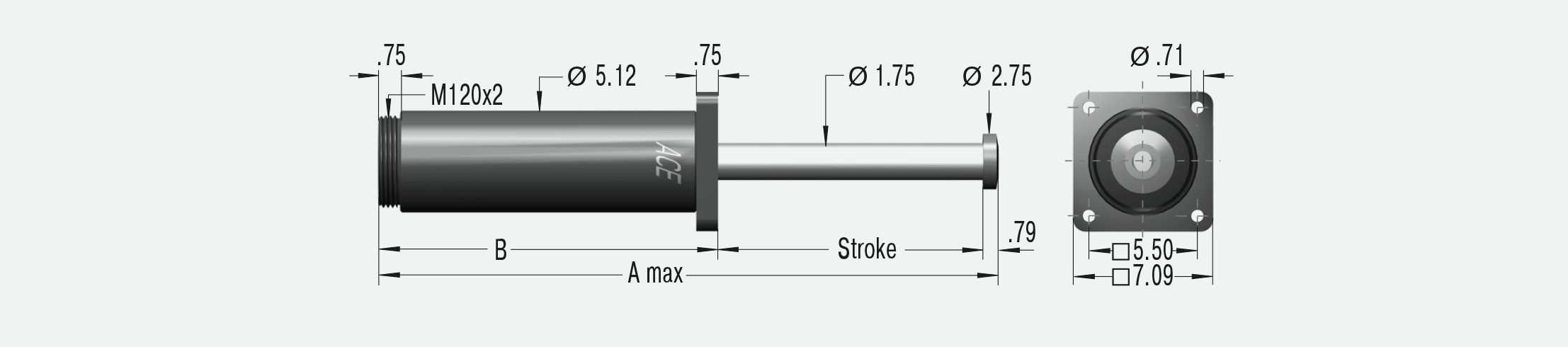

Dimensions

| Stroke | 9.84 inch |

| A max. | 27.17 inch |

| B | 16.54 inch |

| D | 15.16 inch |

| E max. | 11.32 inch |

Technical Data

Energy capacity 310,000 in-lbs/cycle Reacting Force At max. capacity rating = 18,000 lbs to 47,200 lbs lbs Return Force min. 225 lbs Return Force max. 270 lbs F and S R Impact velocity range 2 ft/sec to 15 ft/sec Operating temperature range -4 °F to 140 °F. Other temperatures on request. Mounting In any position Positive stop Integrated Material Outer body, Rod end button: Steel corrosion-resistant coating; Piston rod: Hard chrome plated steel Damping medium Automatic Transmission Fluid (ATF) Filling pressure Approx. 29 psi. Rod return by integrated nitogen accumulator. | NoteThese slimline, high-performance safety shock absorbers are only designed for emergency stop situations. They can be used for a number of tasks in gantries and conveyor systems, processing centres or assembly machines. On requestSpecial oils, special flanges, additional corrosion protection etc. Integrated rod sensor for indicating the complete extension of the piston rod. Type normally closed or normally open, option PNP or NPN switch. |

Application Examples

Application Areas

- Shelf storage systems

- Heavy load applications

- Outer body, Rod end button: Steel corrosion-resistant coating; Piston rod: Hard chrome plated steel

- Conveyor systems

- Portal systems

- Test stations